Introduction

DBV valves short for Double Block and Bleed Valves, are advanced engineering components designed to provide enhanced safety and efficiency in fluid control applications. These valves offer a unique combination of double block and bleed functionalities, enabling the isolation of two different fluid systems and the venting of the cavity between them. This article explores the significance of DBV valves in various industries, their distinct features and benefits, and their role in streamlining fluid control for precision engineering.

The Importance of DBV Valves in Precision Engineering

In precision engineering, the accurate control and isolation of fluids are of paramount importance. DBV valves have emerged as essential tools to meet these demands, particularly in industries where safety, reliability, and precise operation are critical. These valves are widely used in oil and gas, petrochemical, chemical processing, and power generation industries, among others.

To ensure optimal performance, maintenance practices such as regular inspection, proper lubrication, and timely replacement of worn-out seals are recommended. Keeping these systems in prime condition helps prevent operational disruptions and supports overall system reliability. Additionally, operators are encouraged to maintain detailed records of valve performance and service history to track efficiency trends over time.

Double Block and Bleed Functionality

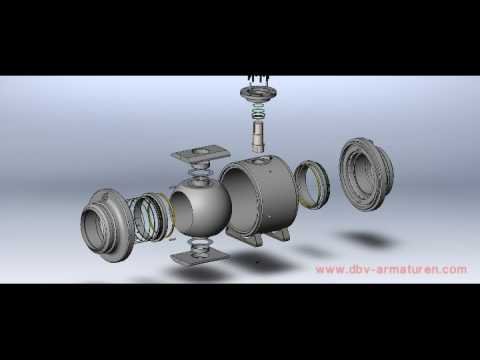

DBV valves are unique in their design, incorporating a double block and bleed mechanism in a single unit. This means that they can provide two independent isolation barriers to block fluid flow in both directions. Industrial Valves have a valve cavity between the two barriers that can be bled to release any trapped fluids or gases, ensuring complete safety during maintenance or shutdown procedures.

In many industrial applications, this functionality reduces the need for additional manual isolation steps, allowing teams to perform complex operations with minimal downtime. Engineers often design these systems with redundant monitoring to quickly detect leaks or pressure drops, which further enhances operational safety.

Enhanced Safety and Environmental Protection

The double block and bleed design of DBV valves offers exceptional safety benefits, preventing cross-contamination and leakage between different fluid systems. This feature is especially crucial in applications involving hazardous or toxic materials. By providing a reliable and robust sealing mechanism, DBV valves minimize the risk of spills and emissions, thereby protecting the environment and personnel.

Environmental protection measures often include installing sensors and alarms that notify operators of potential leaks. Combined with proper valve operation, this approach minimizes both human risk and ecological impact, aligning with stringent environmental regulations.

Efficiency and Space Optimization

In installations where space is limited, DBV valves offer a significant advantage by consolidating the functionalities of multiple valves into a single unit. The double block and bleed capabilities eliminate the need for separate isolation and venting valves, streamlining the fluid control system and reducing the overall footprint of the installation. This optimization not only saves space but also reduces maintenance efforts and costs.

Moreover, engineers often integrate monitoring devices and automation into these compact units, enabling real-time data collection and remote operation. This approach saves both time and manpower while optimizing overall plant efficiency.

Applications of DBV Valves

Oil and Gas Industry: In offshore platforms and onshore processing facilities, DBV valves are used to isolate different production lines, ensuring safety during maintenance and facilitating efficient shutdown procedures.

Petrochemical and Chemical Processing: DBV valves are employed in chemical plants to prevent the mixing of different chemicals, protecting equipment and personnel from potential hazards.

Power Generation: In power plants, DBV valves are utilized in critical areas such as steam, water, and fuel systems, safeguarding against leaks and ensuring seamless operation.

Refining and Pipelines: DBV valves are deployed in refineries and pipelines to isolate and bleed sections for maintenance, reducing downtime and enhancing operational efficiency.

Additionally, these systems are often integrated into large-scale industrial networks where coordination between multiple valves is critical. Simulation testing is frequently conducted to predict system behavior under extreme conditions, ensuring reliability even during emergencies.

Distinct Features of DBV Valves

Compact Design: DBV valves are engineered for space optimization, making them suitable for installations with limited available space.

Robust Construction: Dbaovalve.com manufactures by using high-quality materials such as stainless steel or exotic alloys, ensuring durability and resistance to corrosive environments.

Bi-Directional Sealing: The double block and bleed functionality allows for bi-directional sealing, providing reliable isolation in both flow directions.

Fire-Safe Design: Many DBV valves are designed to meet fire-safe standards, ensuring they can withstand high temperatures and maintain their integrity during fire incidents.

Automated Operation: DBV valves can be equipped with automation systems, allowing for remote operation and integration into complex control systems.

Conclusion

These precision-engineered valves are indispensable components for fluid control, offering multiple functionalities in a single compact unit. They ensure safety, operational efficiency, and environmental protection while reducing maintenance efforts and system complexity. Industries that prioritize safety and sustainability will continue to rely on these innovative solutions for precision fluid management.

By integrating modern monitoring and maintenance practices, operators can maximize performance and reliability. This makes them not only essential for current applications but also critical for future-ready industrial systems. As global industry standards evolve, these systems will remain at the forefront of efficient and safe fluid control solutions.

Read more: What Is A Major Service? Why Is It Critical For Your Vehicle?